Top Types of Ground Engaging Tools for Construction Equipment

Understanding Ground Engaging Construction Equipment

In construction, the right equipment makes a measurable difference. Ground engaging construction equipment is designed to contact the earth directly, handling digging, grading, leveling, and material movement efficiently. Common machine types include excavators, bulldozers, and backhoes.

Excavators handle deep digging and heavy lifts, bulldozers excel at pushing soil and debris, and backhoes combine digging and loading in one machine. Choosing the correct equipment for your application improves productivity, precision, and cost control and helps extend the service life of your ground engaging tools and wear parts.

Why Ground Engaging Tools Matter

Ground engaging tools (GET) make direct contact with soil, gravel, and rock. They take the abrasion and impact so your buckets, blades, and undercarriage last longer. When you choose the right tools and maintain them well, you can:

- Boost digging and grading efficiency

- Improve cut precision and operator control

- Reduce repair and replacement costs

- Extend service life for buckets, blades, and high-wear surfaces

- Increase uptime across your fleet

The Main Types of Ground Engaging Tools

1) Bucket Teeth and Adapters

Teeth and adapters take the first impact during excavation. Tooth profile and metallurgy drive penetration, breakout force, and fuel use. If you need options across different machine types, start with the Bucket Teeth & Adapters collection.

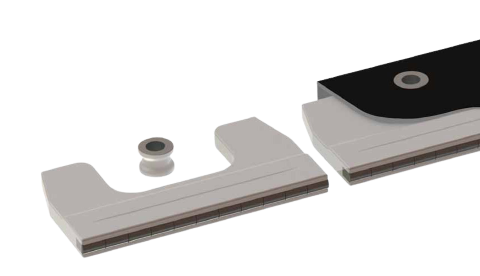

2) Cutting Edges and Blades

Cutting edges create a sharp surface on graders, loaders, and dozers. Many are reversible or bolt-on to speed changeouts. For motor grader applications, compare sizes and profiles in Grader Blades and Motor Grader Cutting Edges. For dozer wear packages, browse Bulldozer Cutting Edges.

3) Ripper Shanks and Teeth

Rippers break compacted or frozen ground so the primary pass is faster and cleaner. The right shank and tooth reduce hydraulic strain and improve traction. See Rippers & Ripper Teeth for a range of sizes and mounting styles.

4) Side Protection and Corner Reinforcement

Side wear can shorten bucket life. Adding protective components and corner reinforcement helps maintain bucket geometry and reduces shell repairs. For plate, bar, and formed protection options, check Bucket Wear Steel.

5) Wear Bars, Liners, and Shrouds

High-impact zones, bucket bottoms, heels, and moldboards, benefit from extra protection. Reinforcement pieces spread impact, resist abrasion, and simplify future maintenance. Start with standard shapes in Wear Steel, then add consumables like carbide to improve life in abrasive conditions: Carbide Bits & Boards.

Top Machine Types & Brands Using Ground Engaging Tools

Match tool types to real machines and OEM ecosystems. Use these brand collections to filter for compatible wear parts:

- Excavators & Backhoes — popular GET: bucket teeth, adapters, side cutters, heel shrouds. Brand collection examples: Caterpillar, John Deere, Komatsu, Volvo.

- Bulldozers / Dozers — common GET: center edges, end bits, corner and heel shrouds. Bulldozer Cutting Edges.

- Motor Graders — reversible edges, serrated profiles, side bits, and moldboard protection. Motor Grader Cutting Edges.

- Wheel Loaders & Skid Steers — base edges, bolt-on edges, wear bars, liners. Collections: Wheel Loader Edges, Skid Steer Edges, plus brand-specific: Bobcat.

How to Choose the Right Ground Engaging Tool

- Ground conditions: Softer soils benefit from lighter profiles; rock and abrasive mixes call for harder alloys or carbide.

- Machine size & power: Match edge thickness, tooth style, and hardware to the hydraulic capacity and base edge.

- Application: Digging, grading, and ripping each favor different geometries, hole patterns, and profiles.

- Changeout speed: Use bolt-on or hammerless systems for fast swaps and safer field work.

- Total cost: Tougher materials cost more up front but can cut downtime and labor over the season.

Maintenance Tips to Extend Tool Life

- Flip or rotate reversible edges to even wear

- Torque hardware on a set schedule

- Keep mounting surfaces clean and flush

- Replace worn components before they undercut base material

- Stage spare edges, teeth, and hardware to avoid downtime

Frequently Asked Questions

What are ground engaging tools?

Replaceable components—teeth, edges, rippers, liners, and shrouds—that contact the ground and protect major equipment structures.

Why are they called wear parts?

They are designed to take abrasion and impact, preserving buckets, moldboards, and frames.

How often should they be replaced?

Set daily inspection habits. Replace when cutting edges round over, crack, cup, or when digging performance drops.

Which tools work best for rocky or abrasive conditions?

Harder, thicker edges and carbide-reinforced systems. Compare options in Grader Blades, Motor Grader Cutting Edges, and Carbide Bits & Boards.

Do all machines use the same GET?

No. Mount patterns, thicknesses, and profiles vary. Use model-specific filters within collections like Teeth & Adapters and Bulldozer Cutting Edges.