Add Carbide to Existing Cutting Edges

We can take OEM part numbers and add carbide to areas of the parts that wear prematurely. Adding carbide to blades has proven to greatly extend the wear life - approximately 8-10 times that of a standard through hardened edge.

Ask for Carbide in Your Quote

The 3X flex lasts up to 3X longer, cleans 3X better, runs super quiet, lightweight, and easy to handle. It includes a 12" carbide segments that flexes and conforms to the road surface. This style of snowplow blade is possibly the most widely use blade ever made. Call us for a quote to outfit your fleet today.

VULCANIZED RUBBER WITH CARBIDE

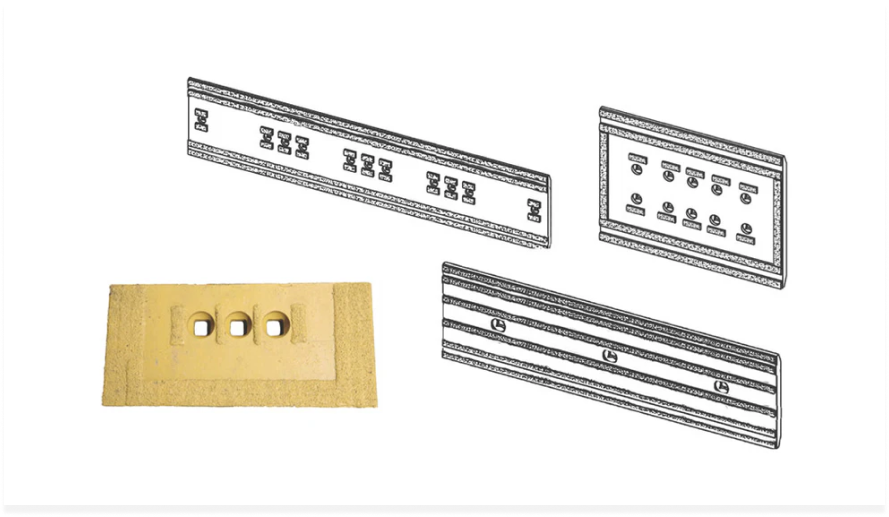

Carbide Grader Blades are a superior choice for any low impact, high abrasion application. The inserted carbide teamed with abrasive resistant carbide insert/carbide impregnated significantly extends the life of the parent material when used in applications where "face" wear is a problem. Tungsten carbide inserts result in a carbide grader blade that will have extremely long wear life. This allows for fewer grader blade changes and and excellent resistance to "crowning" for applications that require a level grading operation.

Shop Grader Blades

For Snow Plows

Equipment Blades Inc. snow plow blades can be broken down into two categories:

TRADITIONAL SINGLE INSERT CARBIDE SNOW PLOW BLADES:

Low cost and more wear life than steel edges.

ADVANCED CARBIDE INSERT SNOW PLOW BLADES:

Modified carbide snow plow blades designed to increase wear life and performance. These advanced carbide plow edge options typically outlast a traditional single insert carbide by two or more times.

Shop Snow Plow Blades

For Carbide Bits & Bolts

Tungsten carbide-tipped bits outlast regular steel blades and will save you time and money. Easily replace worn bits individually without the need for special tools. Carbide bits for motor graders & groomers can be broken down into two main categories:

Rotating Carbide Bits

Rotating Carbide Scarifier Bits for motor graders and groomers are self-sharpening for more uniform wear and longer life. Similar carbide scarifier bits would be used in asphalt milling applications as well. The key to long wear life is maintaining carbide teeth rotation. There are numerous rotating carbide tooth options available for all applications. We recommend going with a carbide rotating bit option that has a washer to separate the bit from the board and help keep grime out. As soon as the bits stop rotating the operator is prematurely wearing the carbide bits. Proper maintenance and check up should be done to make sure the carbide bits are properly rotating.Tip: Some operators will spray diesel or WD-40 on their scarifire carbide rotating teeth to help keep the bits clean and rotating. To winterize your bits and board, clean the grime out of the bits and apply a layer of diesel as lubricant. Make sure to store the bits and boards in the shop or storage out of the freezing weather conditions.

Non-Rotating Carbide Bits

Non-rotating "triangular" carbide bits for motor graders and groomers have great penetration and wear life. The carbide teeth are made up of steel and carbide inserts that allow for these bits to hold up well in all conditions and applications. These carbide bits hold in the board with a universal snap ring so they are easy to change out. Non-rotating carbide bits are what we recommend for front mount grader groomers. They can also be used on the moldboard of a motor grader for extreme wear life.No matter which style you decide to go with, carbide scarifier bits are ideal for dirt and gravel road maintenance; removal of gravel road washboards; hard-packed snow and ice removal; chip and seal road reclamation; tar sand road reclamation; spot asphalt milling; spreading loose material; mixing calcium chloride, magnesium chloride, or other dust suppressants.

CUTTING EDGES

Bulletproof Double Carbide

Add carbide to the surface and a milled slot inside of the blade. Our Bulletproof Double Carbide application not only extends the wear life of the blade, it requires fewer blade changes and less blade crowning.

Download Form

Download Form