Carbide Bits & Boards

Filters

Part #: BIT 1590311

Part #: BIT 1590311

Part #: BIT 1590312

Part #: BIT 1590312

Part #: BIT 1590317

Part #: BIT 1590317

Part #: BIT 1590318

Part #: BIT 1590318

Part #: BIT KR112

Part #: BIT KR112

Part #: CAT 1055180

Part #: CAT 1055180

Part #: CAT 1055183

Part #: CAT 1055183

Part #: CAT 6Y4339

Part #: CAT 6Y4339

Part #: CAT 6Y4340

Part #: CAT 6Y4340

Part #:

Part #:

Part #: BIT 2100-36-34

Part #: BIT 2100-36-34

Part #: BIT 2100-48-34

Part #: BIT 2100-48-34

Part #: BIT C855HDX

Part #: BIT C855HDX

Part #: BIT C855LR

Part #: BIT C855LR

Part #: BIT C858KCSB

Part #: BIT C858KCSB

Part #: BIT C87KCSBSR

Part #: BIT C87KCSBSR

Part #: BIT C87WFRKCSB

Part #: BIT C87WFRKCSB

Part #: BIT C87DSSR

Part #: BIT C87DSSR

Part #: BIT C87HDRP

Part #: BIT RP10

Part #: BIT RP10

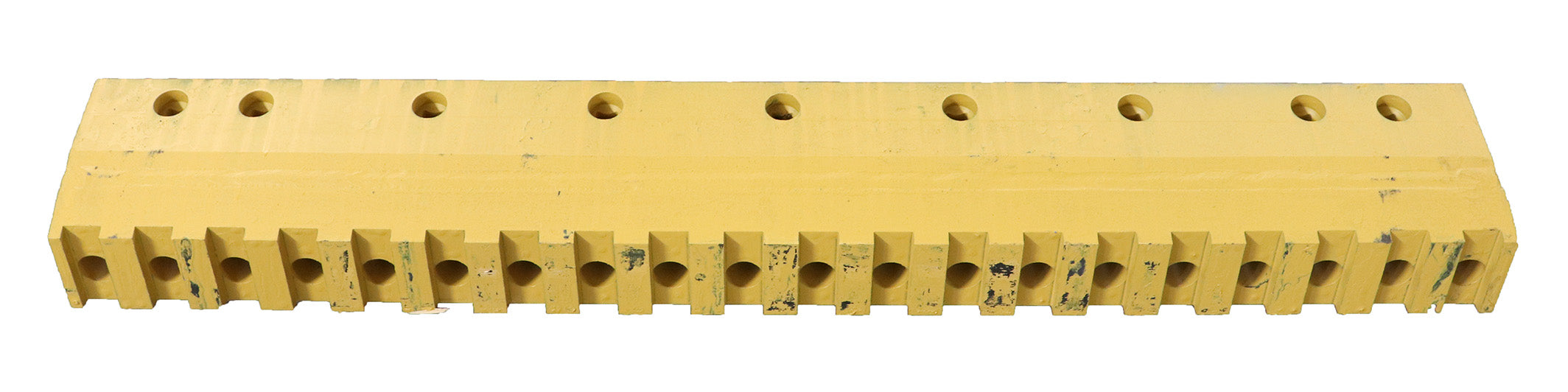

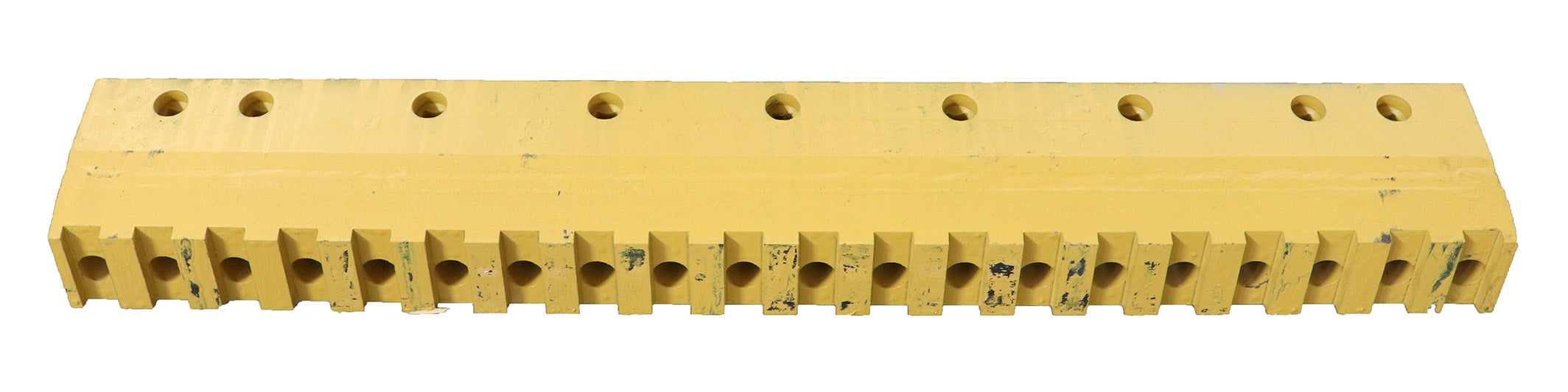

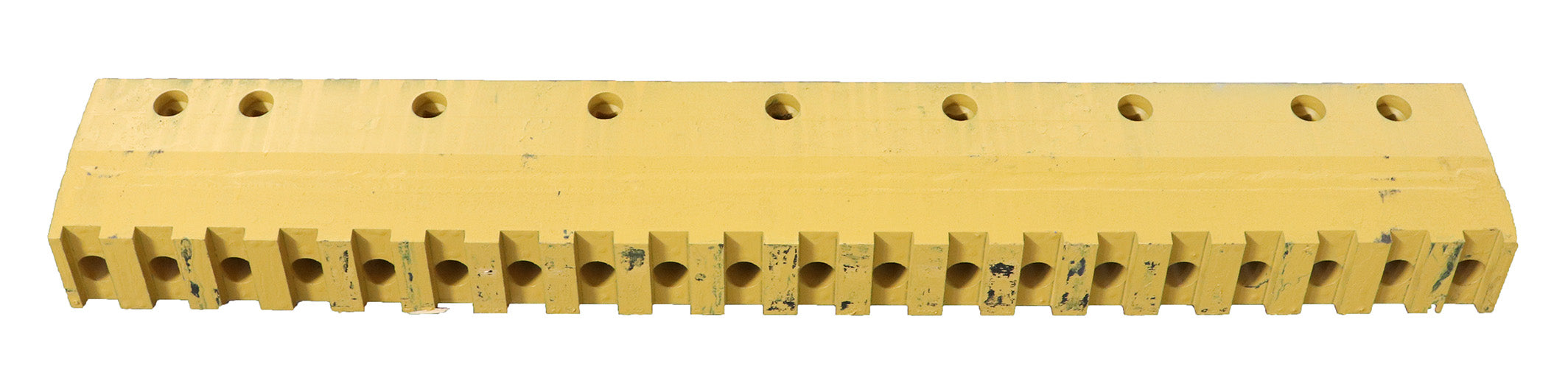

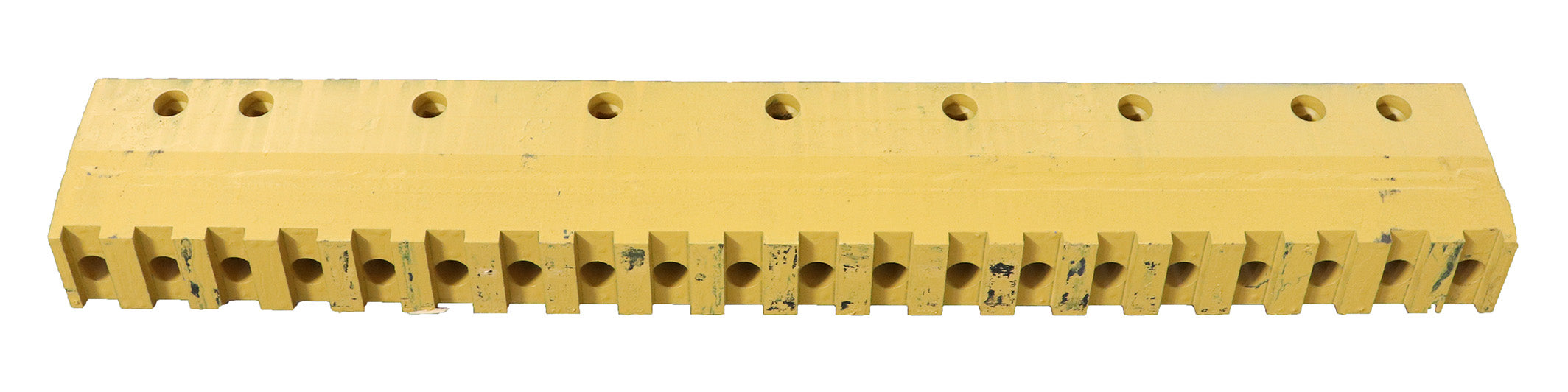

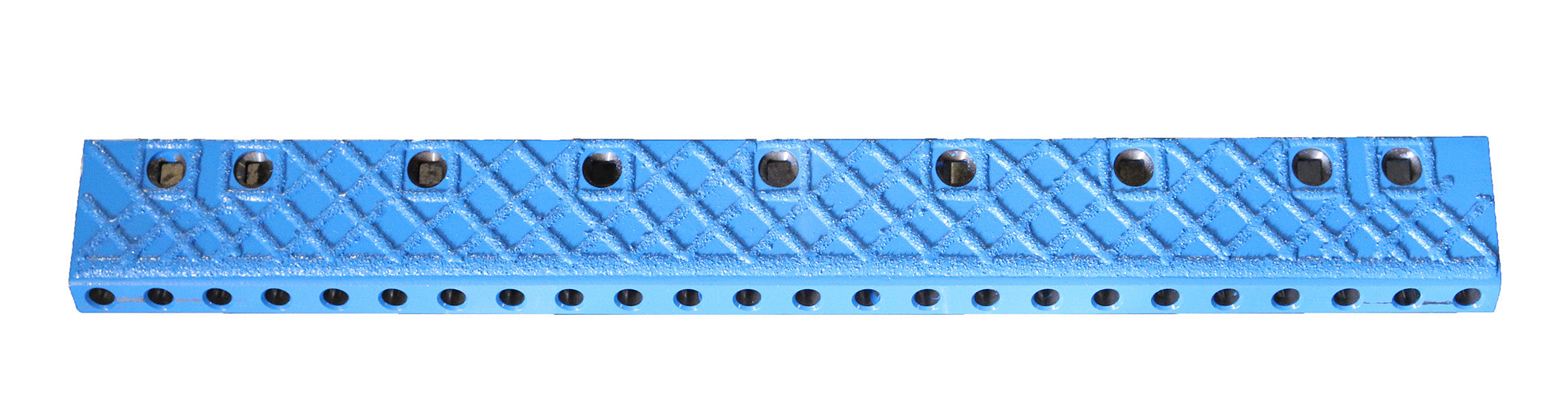

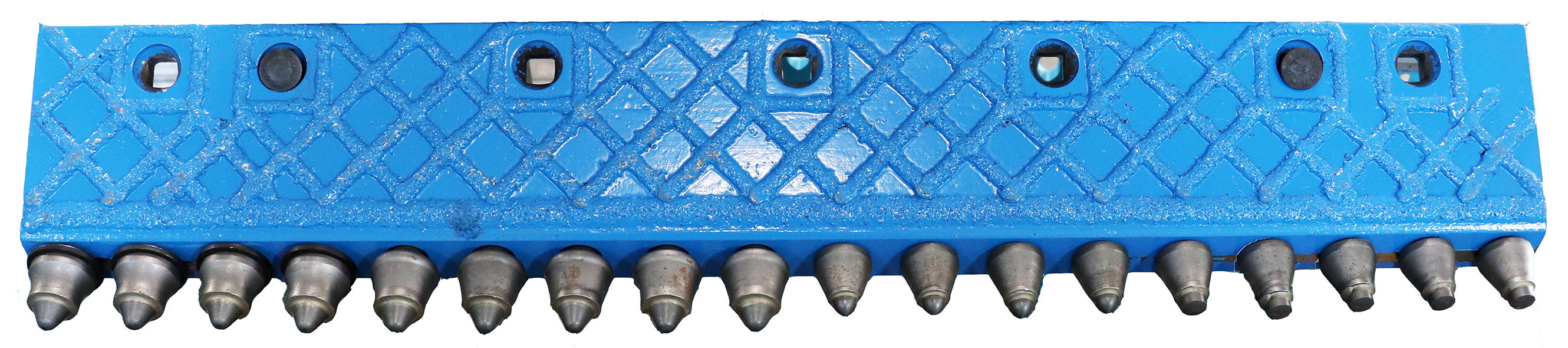

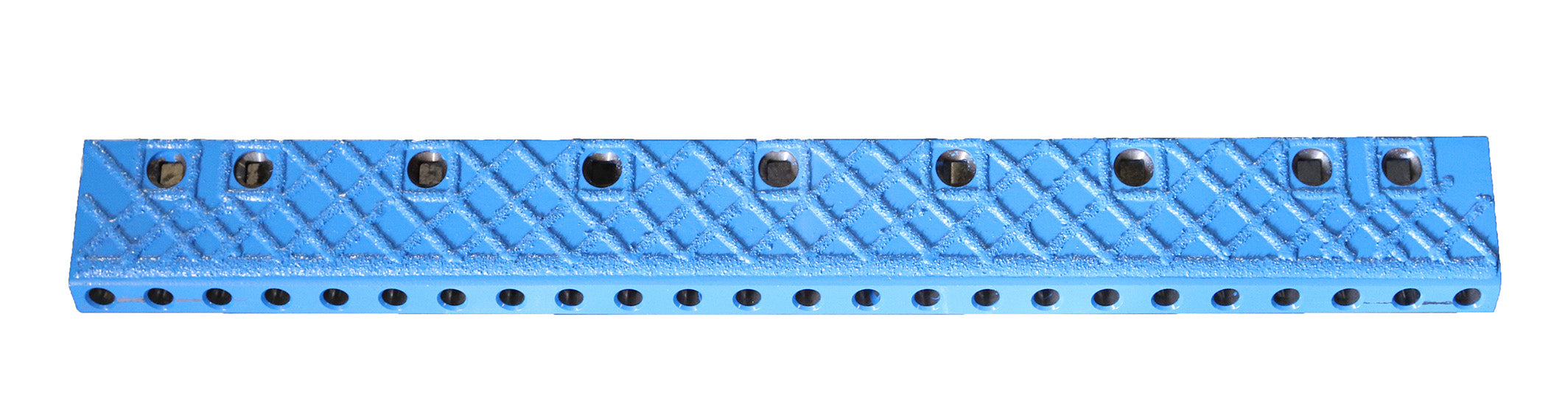

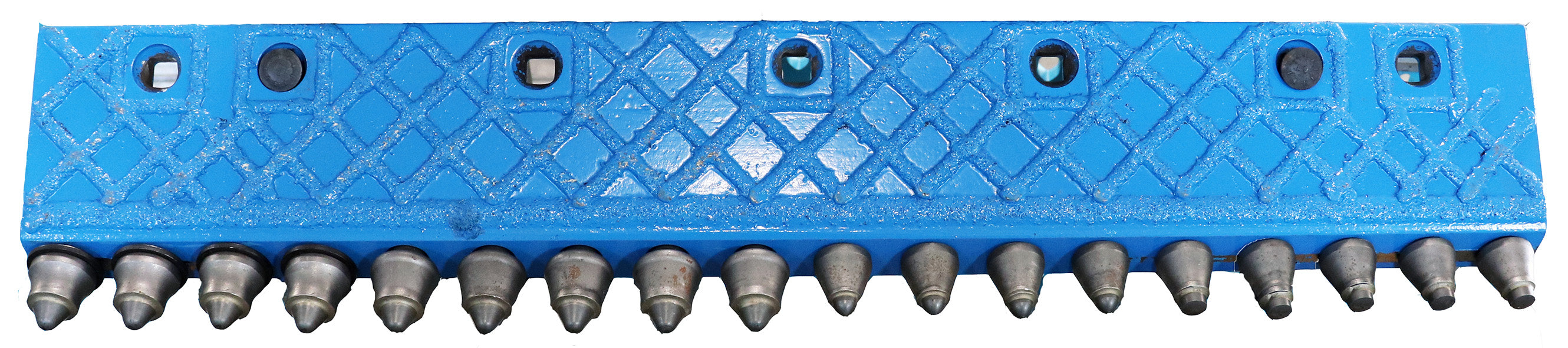

Carbide tipped bits fit in a heavy duty metal bit board designed for heavy duty use and long wear life. They are commonly used on Balderson mounted front groomers for motor graders and can also be put on the moldboard of motor graders.

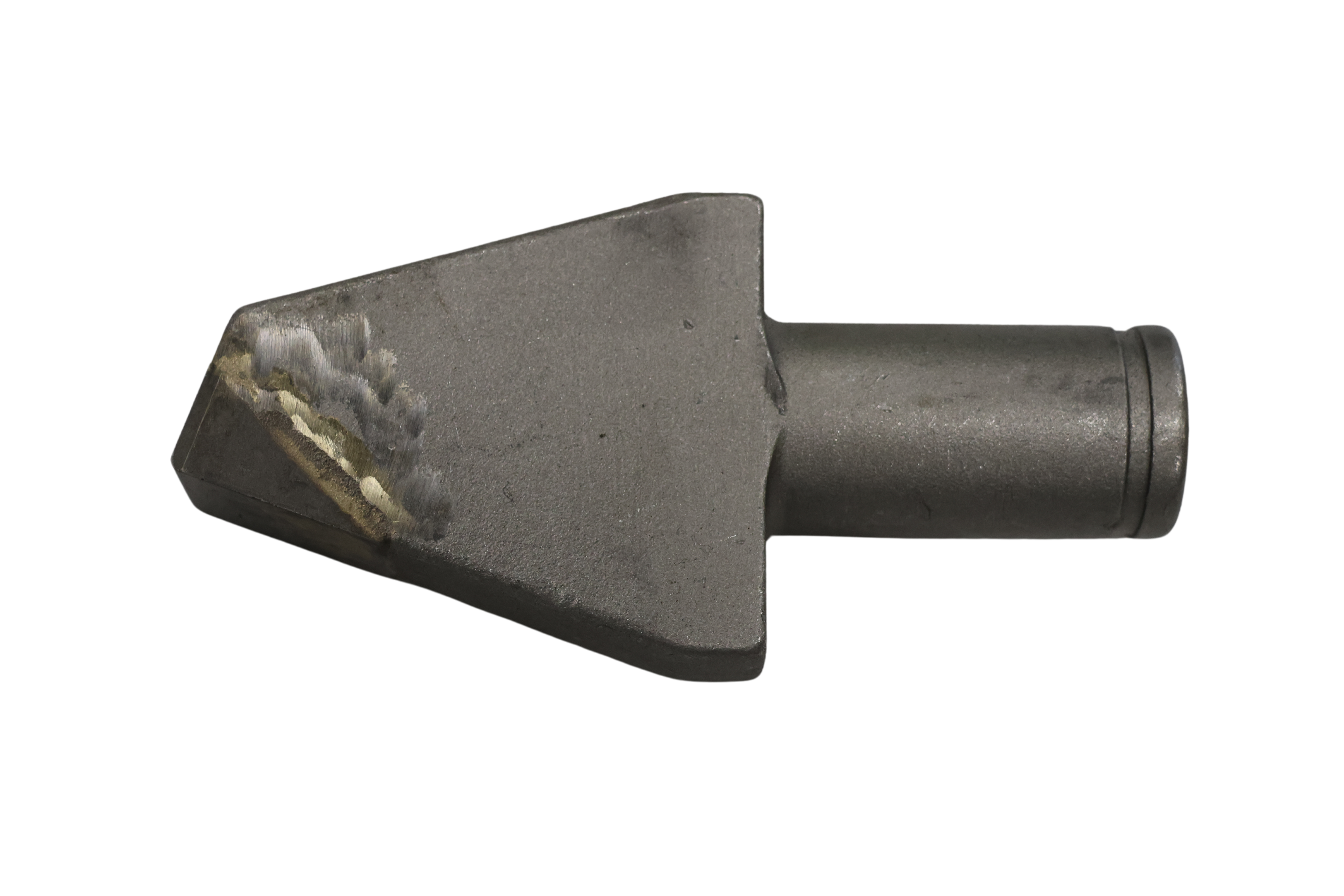

There are different styles and shapes of the carbide bits. The Cat style triangle bits are very long lasting and larger than the conical or rotating style. They are held in place with a snap ring. This cat style does not rotate and they tend to require zero maintenance compared to the rotating conical bits. The Cat style carbide bits also are more aggressive and can dig deeper.

The other common style of conical bits or rotating bits are Kenemetal style or Sandvic style. These are mounted with a internal ring that keeps them secure and help with allowing the rotation of the bit.

Download Form

Download Form