Close

Sidebar

Categories

Recent Post

Wear Equipment FAQ: What Are Snow Plow Blades Made Of?

21 December 2023

7 Best Reasons to Try a New Snow Plow Cutting Edge

13 December 2023

How to Minimize Maintenance of Commercial Snow Removal Equipment

04 December 2023

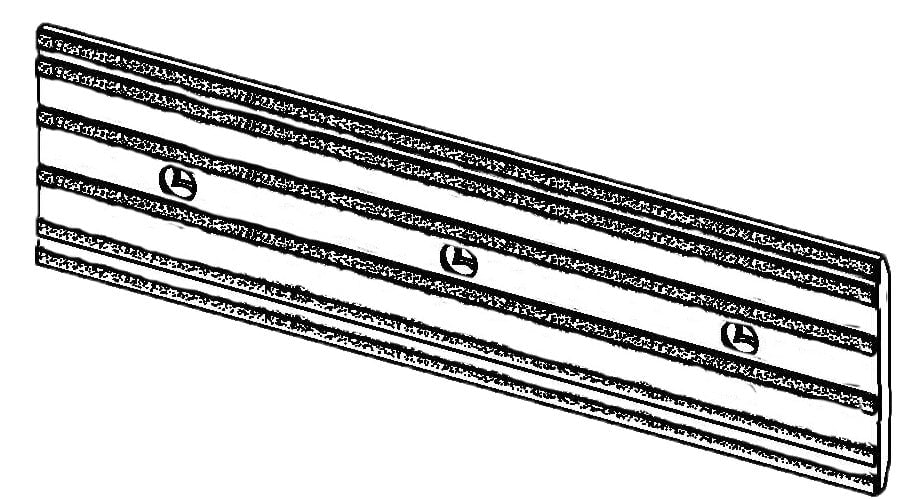

The Ultimate Snow Plow Blade: The 3X Flex Carbide/Rubber Snow Plow Blade

22 September 2023

Why Is Harder Steel Better for Your Cutting Edges?

08 September 2023