1. You will find material you didn't even know you had.

Sharq road grader blades cut deep into the road and pull up material that other cutting edges can't. Check out the video at the bottom of the page to see for your self!

2. You can run your blades with little or no down pressure.

Because these cutting edges cut rather than push, you are able to drop your RPM's by 500 to 1600. This results in a fuel savings of 20% - 50%.

3. The fuel savings will be enough to pay for the blades.

Sharq road grader blades cost a little more than the average blade, but the gas you save by using less down pressure will typically more than pay for your set of blades.

4. Sharq blades last 2 to 4 times longer than regular road grader blades

Along with your fuel savings, Sharq grader cutting edges will cut your costs by lasting longer. That also means you don't have to go through the work of changing the blades as often!

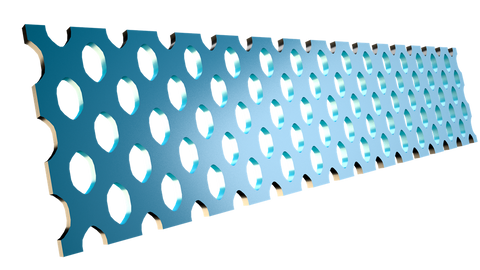

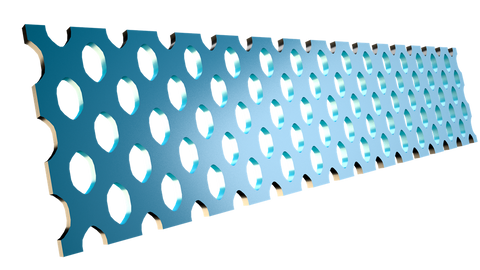

Sharq P-300 Cutting Edge

5. They improve operator environment and save on tire and A-Frame wear.

With less down pressure comes less vibration and less wear. Sharq road grader blades easily cut through the road material, creating a smooth ride. While the blades cut, the moldboard holds the machine down increasing tire traction and decreasing bounce.

6. You can quickly change out cutting edges with just a hammer.

These cutting edges only take about 15 minutes or less to change out. You simply need a hammer, and you can change them out on the road. No need to go back to the shop!

7. You will cut away washboards and potholes and actually fix roads.

Rather than just covering washboards and potholes, you will cut them away and create a new flat surface. Sharq edges actually fix the road rather cover up the blemishes.

8. They create safer roads in both the summer and winter.

Most road grader blades are flat and they leave a flat smooth surface behind. Sharq provides serrated cutting edge options that leave clean fines on gravel and leave a non-slippery surface after cutting ice in the winter.

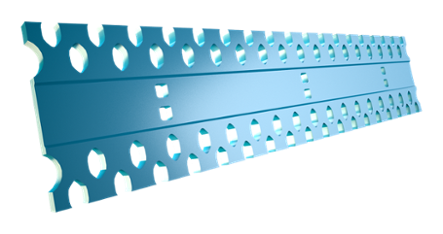

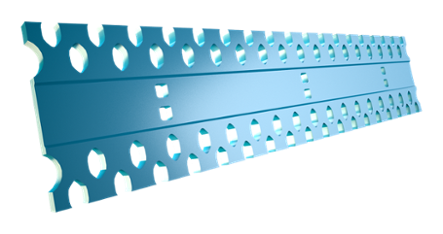

Sharq P-300 HD Cutting Edge

9. Sharq Edges are universal and work on all surfaces: concrete, black top, and gravel.

This means you can use the same tools all year round. You can stock up on the same one or two blades and never worry about changing them for varying road conditions.

10. You will receive more compliments from Joe public rather than complaints.

These cutting edges are for operators who truly care about the work they are leaving behind. They create safe and well-shaped roads that need less maintenance.

Check out how easy Sharq road grader blades are to operate and change out!